.jpg)

Energy efficiency of the house is an important aspect for those who will live in the premises. Maintaining heat and comfort in the building is not so difficult - if you approach this issue correctly at the construction stage. Today, manufacturers offer a variety of materials to solve thermal insulation problems. The list of the most practical ones includes facade thermal panels, which are available in several varieties.

This type of material is a successful tandem in the form of insulation and finishing 2 in 1. In addition, it also provides a facade ventilation option. They are supplied in the format of a modular design with specific dimensions. Thermal panels are installed by fixing them to the wall, providing for the connection of modules with specialized locks. Such a facade system provides the characteristics declared by the manufacturer, suggesting the following list of advantages:

low facade weight, allowing to reduce the load on the base and load-bearing walls;

removal of the "dew point" from the basic structure due to the installation of part of the insulation outside the load-bearing wall;

facade panels with insulation help to reduce the thickness of the walls.

Such thermal insulation of walls provides resistance to external influences, compressive strength and can last for several decades.

In total, there are several types of materials for exterior finishing of a house:

The three-layer format consists of an OSB panel, a polyurethane foam layer, along the perimeter of which there are locks to prevent cold bridges.

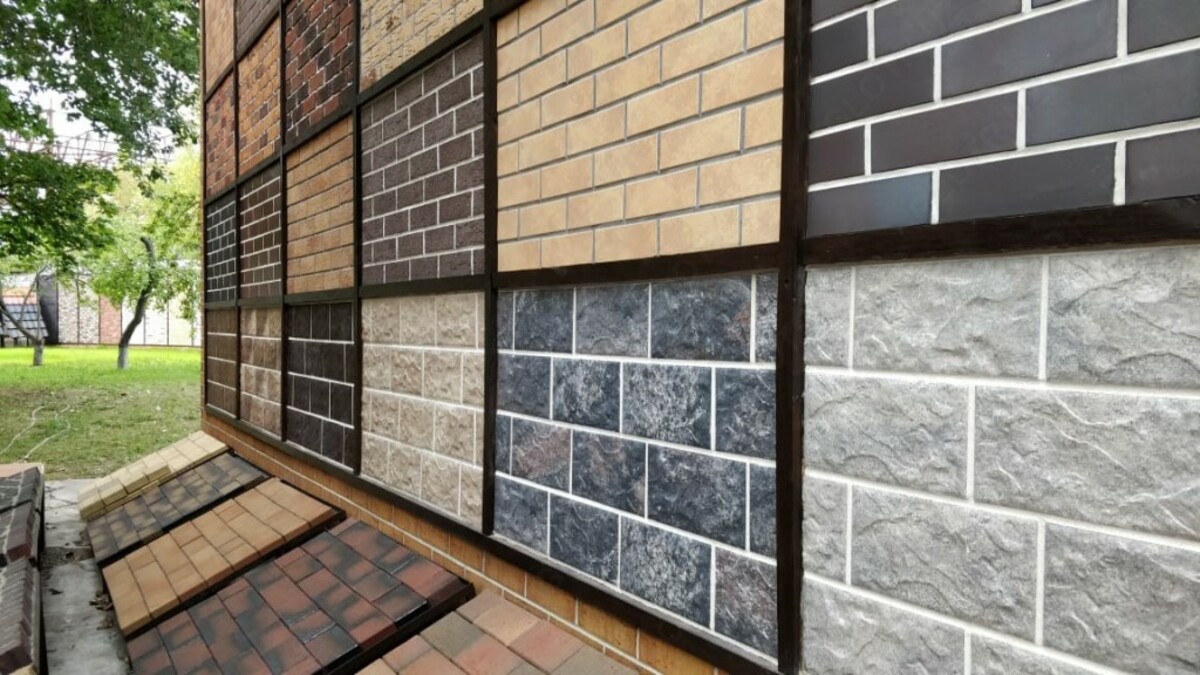

Both of these options provide for installation without wet processes. The second point they have in common is the presence of a finishing coating in the form of acrylic elements or clinker. At the same time, thermal panels with clinker tiles look very stylish and modern.

Such thermal insulation materials are especially in demand when it is necessary to use the structure for a long time. In this case, there is no need to calculate the layer thickness, the amount of raw materials used, strength and thermal conductivity indicators. A panel prepared for installation provides long-term insulation, allowing you to avoid errors during installation work.

The choice of material is carried out taking into account the dimensional characteristics. In addition to the main panels, corner components and additional elements are purchased immediately. If necessary, the blocks can be cut, adjusting the structure to the desired format.

Such products involve turnkey installation of the facade, since they provide everything necessary for this. Environmentally, such products are neutral, allowing for the potential for installation even indoors in specific situations.