Eco-style houses are the latest fashion trends. This type of construction is chosen by those who prefer a modern style and want to live in a safe environment. The choice of materials suitable for this trend is now very diverse. At the same time, the most popular is the facade cladding with imitation timber. For this purpose, a material called block house or false timber (colloquially Euro board) is used, which can be purchased in different colors and textures.

This lumber creates the illusion of a rounded log. It is offered to users in two types - wide and narrow. In the first case, the imitation implies sizes of 160 or 240 mm in diameter, it is used mainly as external facade panels under a tree. Narrow blockhouse is known as decorative lining - it is often used for interior decoration. In short, the system of using this material for a ventilated wooden facade is as follows:

Blockhouse is made of natural coniferous wood - mainly spruce and pine. The manufacturing process involves thorough drying, resulting in a perfectly flat surface that is not subject to deformation and cracks. In addition to exterior finishing of a house, this lumber has proven itself well in cladding walls, building fronts, and balconies.

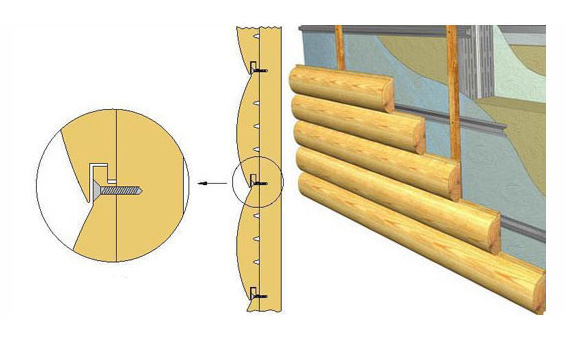

Wide blockhouse is installed horizontally or vertically. Before the main work, it is important to think over the vapor barrier and wind protection aspects. Initially, vapor barrier sheets are laid on the walls, fixing them at the top with aluminum tape. On top of them, vertical lathing made of dry timber is mounted, the thickness of which is identical to the thickness of the insulation. The structure is fastened with dowels. Further installation of the facade on the frame is as follows:

Installation work is carried out from the top or bottom of the wall, leaving a small gap of 1-3 mm between the boards. After installation, the wooden blockhouse is primed and covered with varnish in two layers based on wax.

When preparing a house for a wooden façade, it is necessary to strictly follow all stages of the process. Otherwise, over time, improperly installed thermal insulation and cladding will not bring the desired result in terms of heat preservation and the effectiveness of the exterior design.

.jpg)

Most experts recommend insulating with mineral wool or foam plastic. Both of these materials are characterized by productive results and a long service life. Their other advantages include the following:

Insulation under a block house using mineral wool can also be carried out using special glue, experts supplement it with fasteners. This material is supplied in rolls of a certain width and length, which is very convenient for the installation process.

Considering mineral wool as insulation under a block house, you need to know that it implies several varieties, differing in density. This indicator indicates the resistance of the material in kg per m3. Wool with a density of 35 - 45 kg / m3 is recommended for a block house. The basalt type of wool does not lose its shape and quickly recovers after pressure or loads.

The supply of foam plastic implies ready-to-install slabs of a specific thickness in a different size range. Both materials are easy to process using cutting tools.